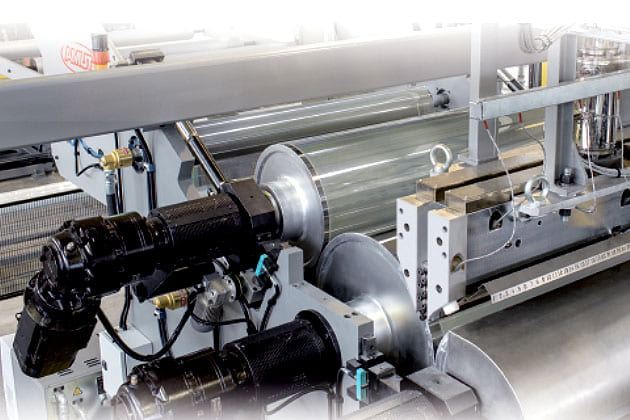

rPET SHEET Extrusion Production System

Lines for rPET SHEET

Direct PET sheet production process from post-consumer PET bottles

The ACI AMUT extrusion system is capable of producing high quality PET sheet from FDA and EFSA certified post-consumer PET flakes. The AMUT-EREMA system, including a decontamination/dehumidification process (approximately 1 hour), completely removes the volatile contaminants remaining in the flakes, producing perfect and unbreakable PET sheets without reducing the viscosity (IV) of PET more than any other system, and can produce PET sheets as thin as 1.5 mm thick.

Applications

- PET Cup

- PET trays – trays, fruit packaging, electronics packaging

- PET thick plate packaging

Features & Advantages

- Produces perfect, unbreakable PET sheets without reducing the viscosity (IV) of PET

- Produce PET sheets down to 1.5 mm thick

- Minimizes sheet thickness of PET thermoformed products

- No limit on the percentage of recycled PET flakes that can be used in thermoforming PET sheets

- Continuous thermoforming with recycled PET flakes is possible

- Highest energy efficiency