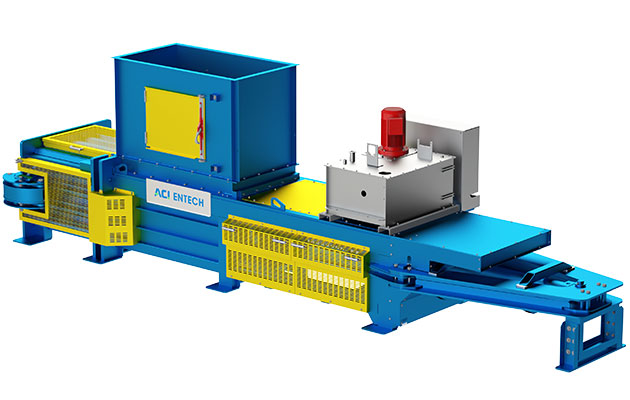

Semi-Automatic Baler

Semi-Automatic Baler

Semi Auto Baler with optional Cross Binding

High Efficiency with One Wire Connection system

Semi-Automatic Baler is to compress various materials into square bale automatically. The bale bindings are done manually by the operator with the vertical and/or cross tying method. Thanks to the guide-tube, the operator can finish the tying work very quickly. The Level Sensors integrated in the feeding hopper help to control the pressing cycle efficiently.

Applications

- Material Recovery Facility(MRF)

- Mechanical Biological Treatment Facility(MBT)

- Waste Paper Compacting Facility

- Plastic Film Compacting Facility

Features & Advantages

- Guide Tube

- One Stop Tying System

- Possible for Operator to finish Tying Work quickly without position change

- Efficient Tying with once tying wire

- Level Sensors installed in Feeding Hopper

- Controlling Pressing Cycle

- Able to measure the feeding level in the hopper

- Low Level Sensor to control the Press Ram

- High Level Sensor to stop the Feeding Conveyor

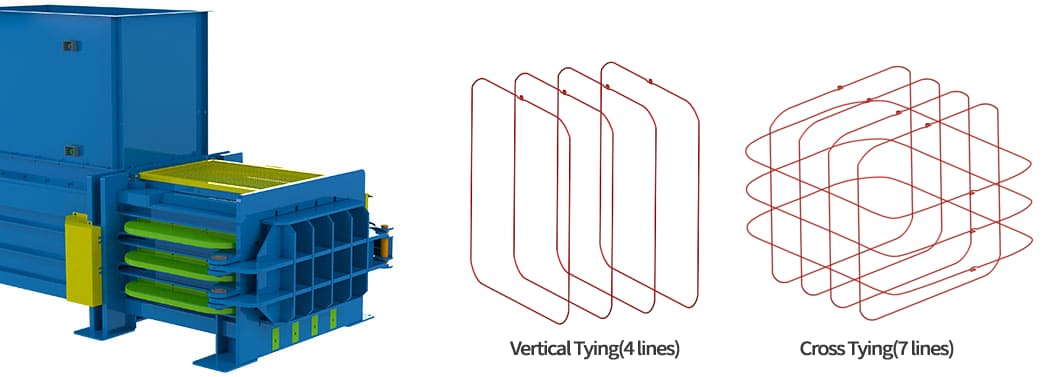

- Two Tying Methods

- Vertical and Cross Tyings

- Able to choose one of Two Tying Methods according to Material Characteristics

- Vertical Tying: big size materials / Cross Tying: small size materials

Products in series

Technical Data

| AVOS 141-15/50 | AVOS 181-15/50 | |

|---|---|---|

| Bale Dimension | W1,100 x H750 | |

| Bale Weight | Max.660kg | |

| Cycle Time | 42sec | 54sec |

| Press Force | 500kN | |

| Power Consumption | 15.0kW | |

| Dimensions (WxLxH) | 2,200 x 7,200 x 2,350mm | 2,200 x 8,080 x 2,350mm |