Renewable Eco-friendly Energy System

VYNCKE's global network ensures customer satisfaction

for domestic and international energy recovery plants.

For more than 100 years, VYNCKE has gained a great deal of expertise in converting biomass and other solid materials biomass and other solid materials into energy.

With more than 4000 installations worldwide, VYNCKE’s experience includes water heaters, steam boilers, thermal oil heaters, multimedia plants (hot gas, thermal oil, steam, power generation in a single system) and cogeneration plants to convert biomass and other solid materials into energy and other solid materials into energy.

With more than 4000 installations worldwide, VYNCKE’s experience includes water heaters, steam boilers, thermal oil heaters, multimedia plants (hot gas, thermal oil, steam, power generation in a single system) and cogeneration plants to convert biomass and other solid materials into energy and other solid materials into energy.

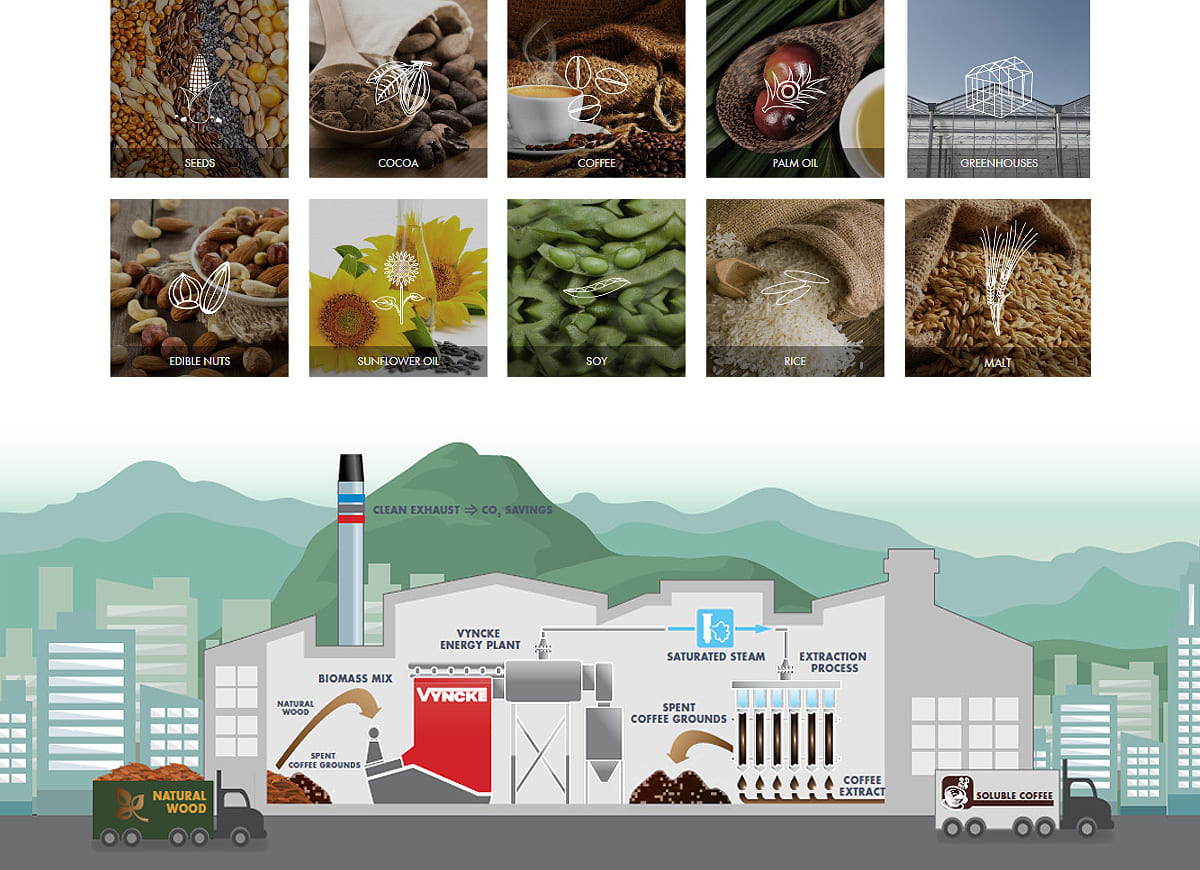

Scope of Business

We burn biomass, bio SRF, and SRF from waste

to produce to produce steam, hot water and electricity.

to produce to produce steam, hot water and electricity.

Combined Fuels

The DWS has evolved into a grate for burning mixed fuels, and a variety of models have been developed.

The DWS-FW model, which is fully water cooled, is suitable for burning fuels with low moisture content or low melting point, while the Semi-Water Cooled model is suitable for fuels with high moisture content.

The DWS-Hybrid model, a combination of both semi-water and full water cooling, combines the best of both worlds and is the most versatile model for complex fuels. With more than 900 grates installed worldwide With more than 900 grates installed worldwide, Vinkesa has a strong reputation for its water-cooled grate models in a wide range of industries using a variety of fuels. The fuels being applied are composite fuels and a wide range of fuel materials. Most solid fuels are burned on the top surface of the DWS, while fines are burned in suspension.

Features & Benefits

- Metered supply for high temperature corrosion and flashback protection

- Water-cooled grate, hybrid grate

- Individual grate control and combustion control for each combustion zone

- High efficiency 1-drum boiler with automatic firing system

Food and agricultural by-products (such as coffee beans)

Coffee spent ground, a by-product from soluble coffee, can be valorized in a VYNCKE energy plant to produce steam for the evaporation and extraction steps or for the drying process.

Business Performance

With more than 100 years of history, VYNCKE has more than

4,000 projects worldwide more than 4,000 installations worldwide

4,000 projects worldwide more than 4,000 installations worldwide

SRF

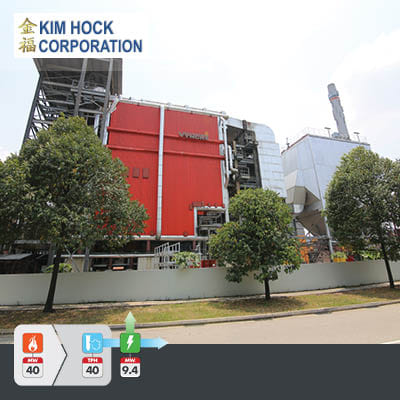

SINGAPORE

SOUTH KOREA

SINGAPORE

WOOD

SPAIN

SOUTH KOREA

SINGAPORE

FOOD & AGRI

GHANA

CHINA

UKRAINE

Facilities

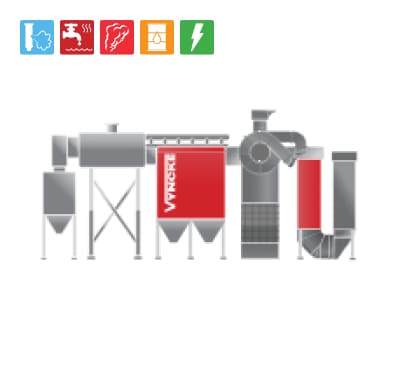

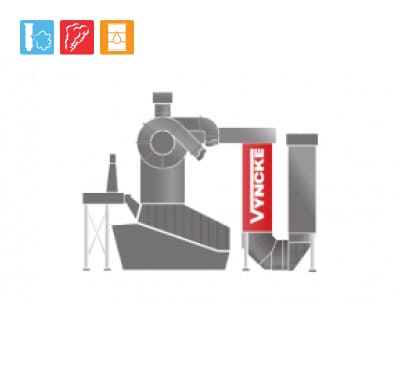

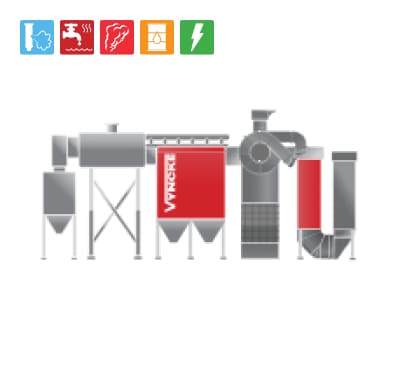

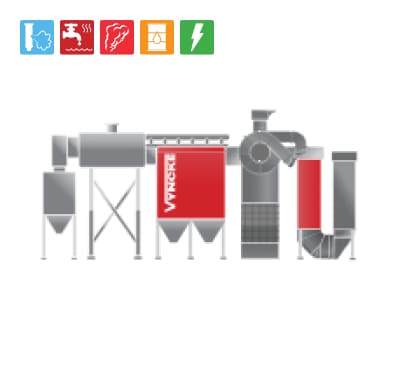

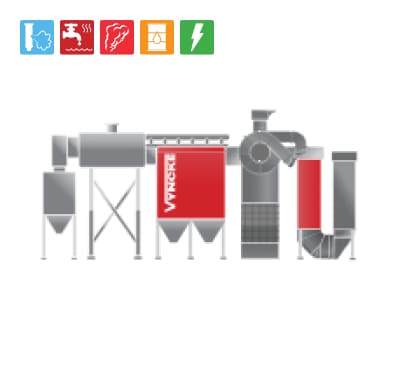

Introducing VYNCKE’s biomass solutions.

Depending on your energy needs, you can find different solutions.

Depending on your energy needs, you can find different solutions.

For more information, please feel free to contact us here

All

Hot Water

Thermal Oil

Hot Gas

Steam

Electricity

MMD-IV

25-100 MW

JNO-R-SH

3-25 MW / 0.5-5 MWe

MMD-II

25-100 MW

MMD-I

25-100 MW

WTB-H

10-100 MW / 1-20 MWe

WTB-V

10-100 MW / 1-20 MWe

JNO-R-SH

3-25 MW / 0.5-5 MWe

JNO-R

3-25 MW

JNO-SH

3-25 MW / 0.5-5 MWe

JNO

3-25 MW

HGG-I

10-100 MW

TFH-II

3-40 MW / 0.5-5 MWe

TFH-I

2-5 MW

CNS

7-20 MW

CNS-C–HG

3-20 MW

CNS-C

3-20 MW

LSS – HW

1-10 MW

LSS-ST

1-10 MW

JNO-R-SH

3-25 MW / 0.5-5 MWe

WTB-V

10-100 MW / 1-20 MWe

JNO

3-25 MW

TFH-II

3-40 MW / 0.5-5 MWe

CNS

7-20 MW

CNS-C–HG

3-20 MW

CNS-C

3-20 MW

LSS – HW

1-10 MW

MMD-IV

25-100 MW

JNO-R-SH

3-25 MW / 0.5-5 MWe

MMD-II

25-100 MW

MMD-I

25-100 MW

TFH-II

3-40 MW / 0.5-5 MWe

TFH-I

2-5 MW

MMD-IV

25-100 MW

JNO-R-SH

3-25 MW / 0.5-5 MWe

MMD-II

25-100 MW

MMD-I

25-100 MW

WTB-H

10-100 MW / 1-20 MWe

HGG-I

10-100 MW

MMD-IV

25-100 MW

JNO-R-SH

3-25 MW / 0.5-5 MWe

MMD-II

25-100 MW

MMD-I

25-100 MW

WTB-H

10-100 MW / 1-20 MWe

WTB-V

10-100 MW / 1-20 MWe

JNO-R-SH

3-25 MW / 0.5-5 MWe

JNO-R

3-25 MW

JNO-SH

3-25 MW / 0.5-5 MWe

JNO

3-25 MW

CNS-C–HG

3-20 MW

LSS-ST

1-10 MW

JNO-R-SH

3-25 MW / 0.5-5 MWe

WTB-V

10-100 MW / 1-20 MWe

JNO-R-SH

3-25 MW / 0.5-5 MWe

JNO-SH

3-25 MW / 0.5-5 MWe